Production and Quality:

Vifra heart and soul

PLASTIC.

WE MOULD IT AND WE CHROME IT.

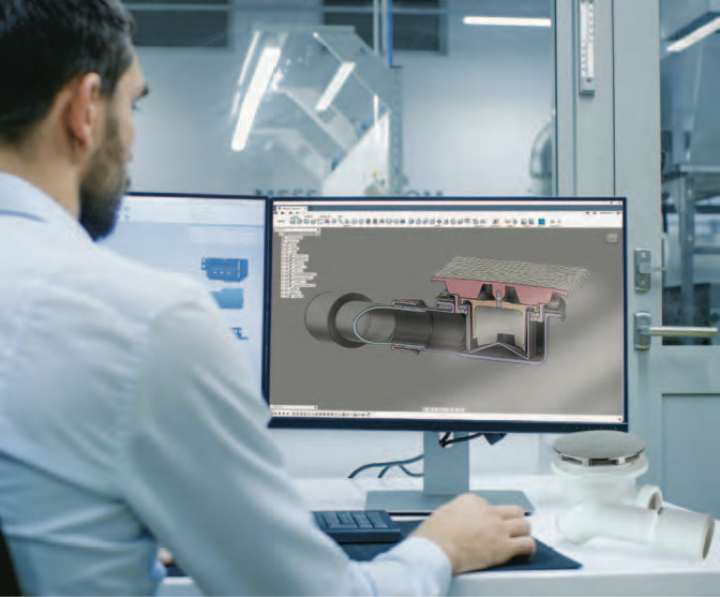

Vifra designs plastic items, builds the production equipment, mould the items and aesthetically finishes them according to the customer’s requests and needs.

Bring us your idea!

Contact us

Bring us your idea!

One solution, more benefits:

- We work in Italy, we take care of everything and we have a know-how that allows us to reach high quality standards.

- Do you work with 10 different companies to develop your product? We manage all the process.

Clients portfolio:

Sectors in which we operate

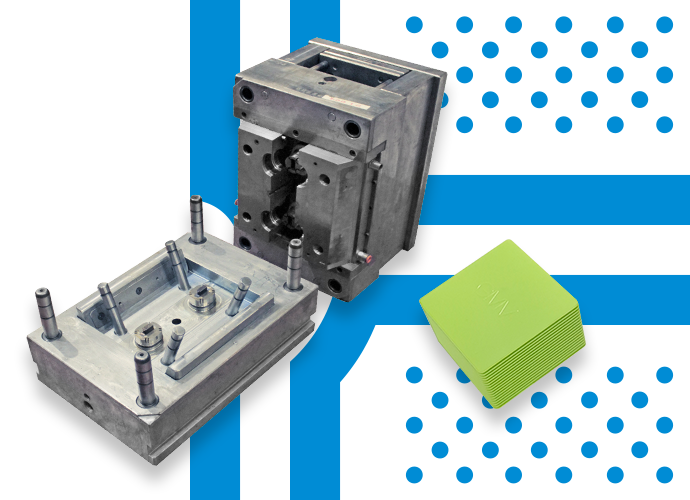

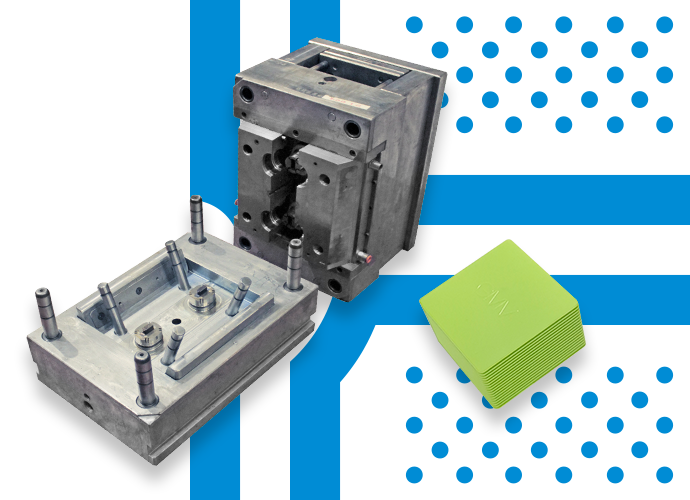

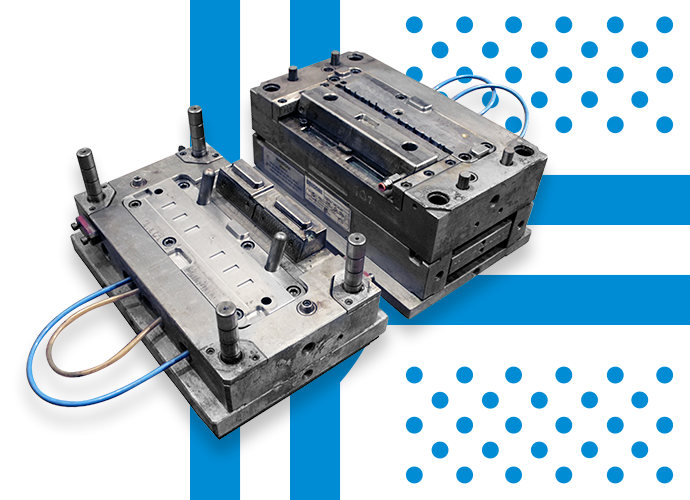

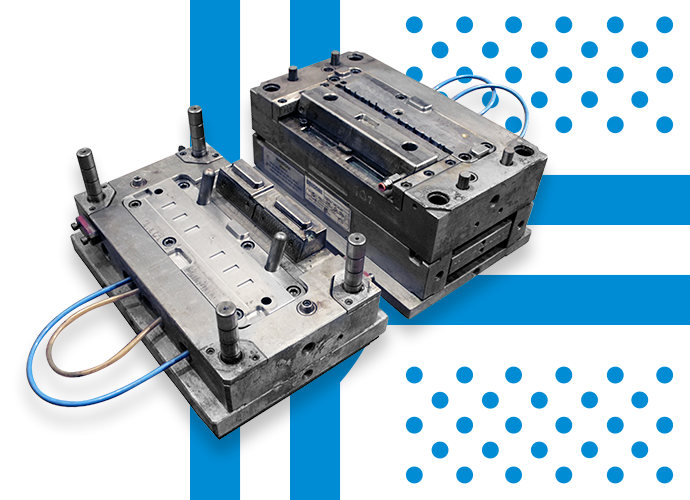

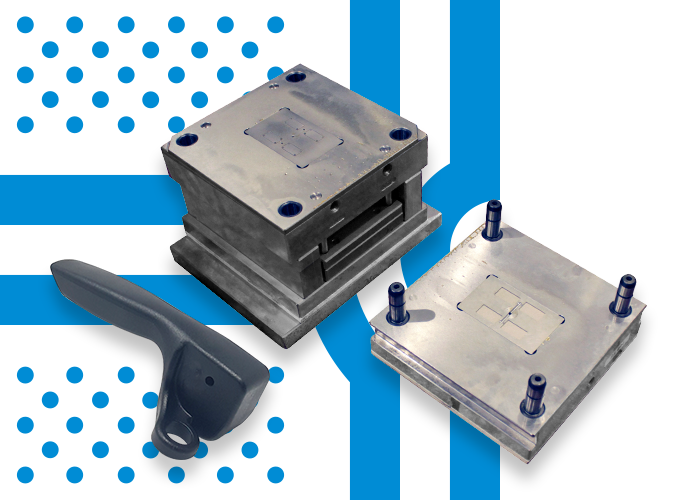

Moulds and Injection moulding

Cosmetics – Perfumery

Moulds and Injection moulding

Cosmetics – Perfumery

Elegance, originality, suggestion: these are the characteristics required for a perfumery product. The majority of cosmetic products are made of plastic, for the lightness, the guarantee of hygiene of the material and the particular aptitude to give shape to the ideas of designers. Find out more

Find out more

Moulds and Injection moulding

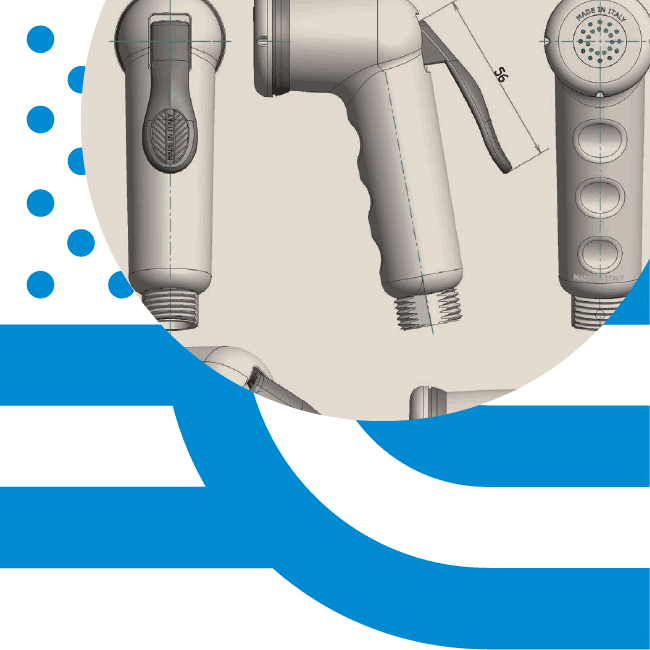

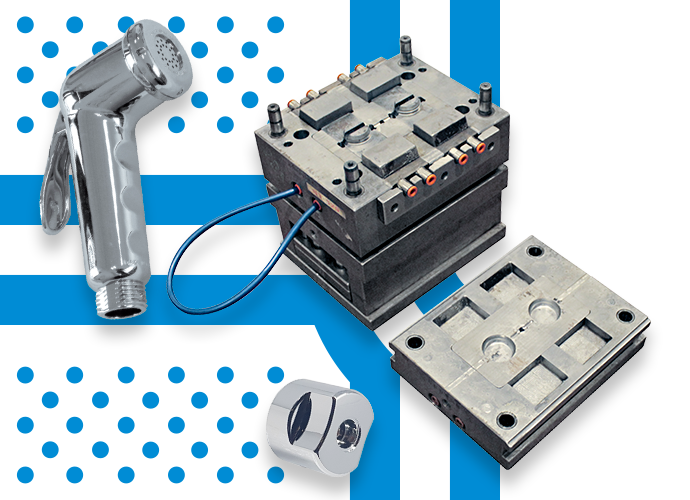

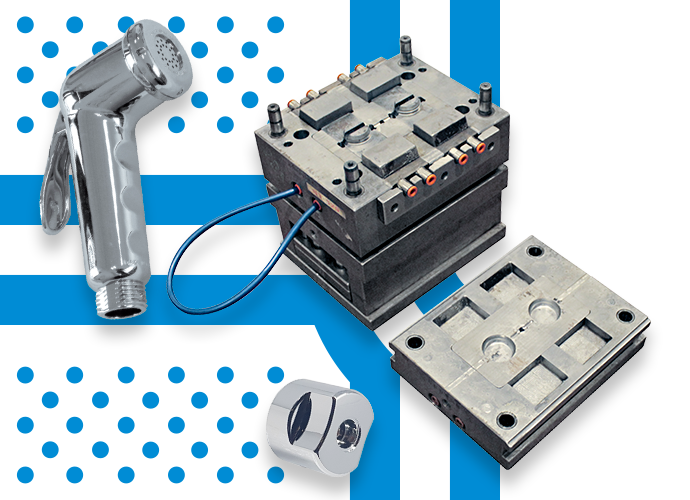

Taps and fittings – Water – Sanitary

Moulds and Injection moulding

Taps and fittings – Water – Sanitary

Plastic components for taps and fittings have definite characteristics: solidity, lightness, functionality and durability. VIFRA production provides for a range of products included in a specific catalogue: from components of the shower to handles, from levers to cover caps, from accessories to drains. Find out more

Find out more

Moulds and Injection moulding

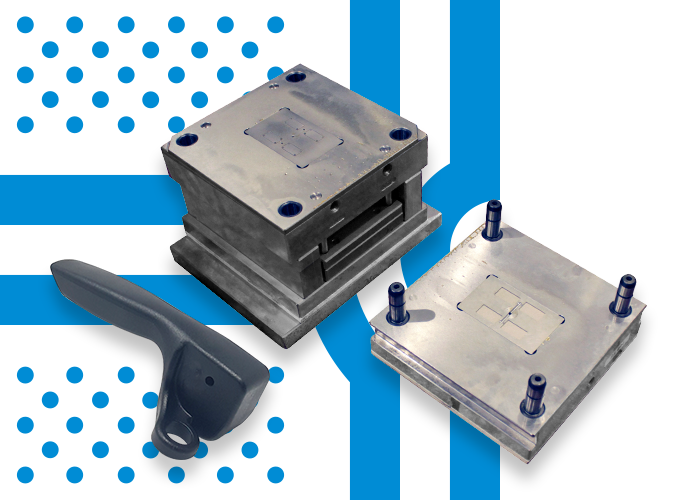

Automotive

Moulds and Injection moulding

Automotive

Many objects are engineered and produced for the automotive industry. The required quality standards are high; perfect chrome plating, strength, weather resistance and durability. VIFRA guarantees, in the relationship with the client, confidentiality and discretion to protect patented or owned items. Find out more

Find out more

Moulds and Injection moulding

Furnishing accessories and home objects

Moulds and Injection moulding

Furnishing accessories and home objects

Plastic is now part of everyone’s life and even our home is an assembly of natural raw materials. Architecture and design has found this material a perfect ally for its flexibility, transparency, colours, ductility and strength. It has also affected its low cost. VIFRA can count among its partner excellent names and products of high aesthetic quality. Scopri di più

Scopri di più

Moulds and Injection moulding

Electric

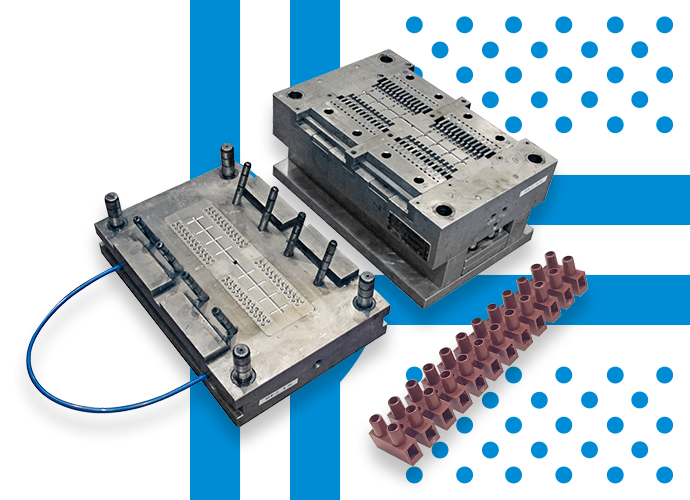

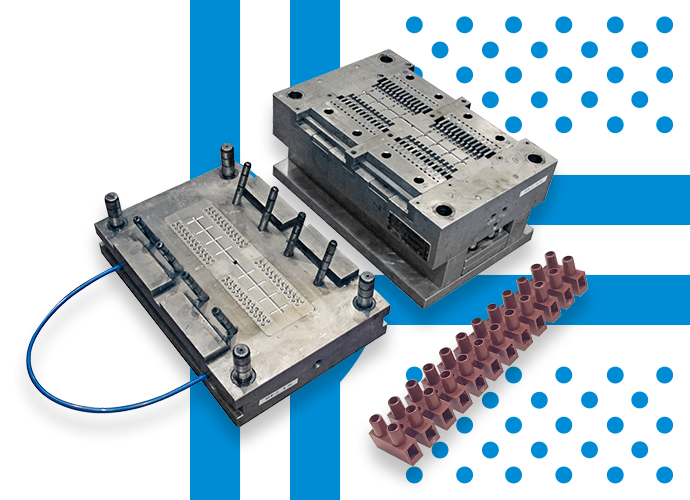

Moulds and Injection moulding

Electric

Plastics are deeply established in the electrical sector. Plastic is essential in terminals, connectors, connecting boxes, clamps and other components that require technical accuracy and reliability of the materials used, which must also serve as coating and insulation of the conductors. VIFRA enters this market with reliable partner and industry experts. Find out more

Find out more

Moulds and Injection moulding

Thermohydraulic – Heating

Moulds and Injection moulding

Thermohydraulic – Heating

The technical properties of plastic, functional and versatile, make it an ideal material for the field of thermohydraulics and home heating. You can find applications in any part of a building, from the roof to the foundation.

VIFRA also in the field of thermohydraulics and heating owns proprietary moulds and a great experience to complete a sector that increasingly uses plastic, even with recycled material guaranteed over time. Find out more

Find out more

VIFRA also in the field of thermohydraulics and heating owns proprietary moulds and a great experience to complete a sector that increasingly uses plastic, even with recycled material guaranteed over time. Find out more

Tailor made

“If you can dream it, you can do it.” – Walt Disney

Bring us your idea, your needs, your sample, and we will study together the best solution for you.

Discover Vifra tailor made

Bring us your idea, your needs, your sample, and we will study together the best solution for you.

“Their experience in plastic molding make Vifra an excellent partner to grow up with.”

“Excellent workers, who know their job. The result is high quality products and innovative solutions.”

“Reliable company made up of serious people.”

“Pleasant and peaceful working place, qualified people, always available and up to the challenge.”

“..Vifra Shattaf Shower, is the best I have used and sold; design, detail and functionality of the Vifra shattaf Plug Kit, all combine to result in a reliable, comfortable and aesthetically attractive essential product. The second generation family owned Vifra, and it’s loyal long serving talented key personell, are a joy for my team and I to work with..”

Stakeholders feedback.

“Plastic is too precious

to be trash”

Special attention for the Green Economy. Continuous research for sustainable materials in order to create products with low environmental impact.