Bring us your idea and your project, we’ll turn it into a product!

The constant new material research, our experience and our technical skills give the client enormous opportunities to give new features to an existent product, without changing the production lines.

In addition, with prototyping, we are also able to create real models for evaluation of functionality or matching with other components.

Design, prototyping,

reverse engineering

Design, prototyping,

reverse engineering

Bring us your idea and your project, we’ll turn it into a product!

The constant new material research, our experience and our technical skills give the client enormous opportunities to give new features to an existent product, without changing the production lines.

In addition, with prototyping, we are also able to create real models for evaluation of functionality or matching with other components.

The constant new material research, our experience and our technical skills give the client enormous opportunities to give new features to an existent product, without changing the production lines.

In addition, with prototyping, we are also able to create real models for evaluation of functionality or matching with other components.

“ We shape your ideas.“

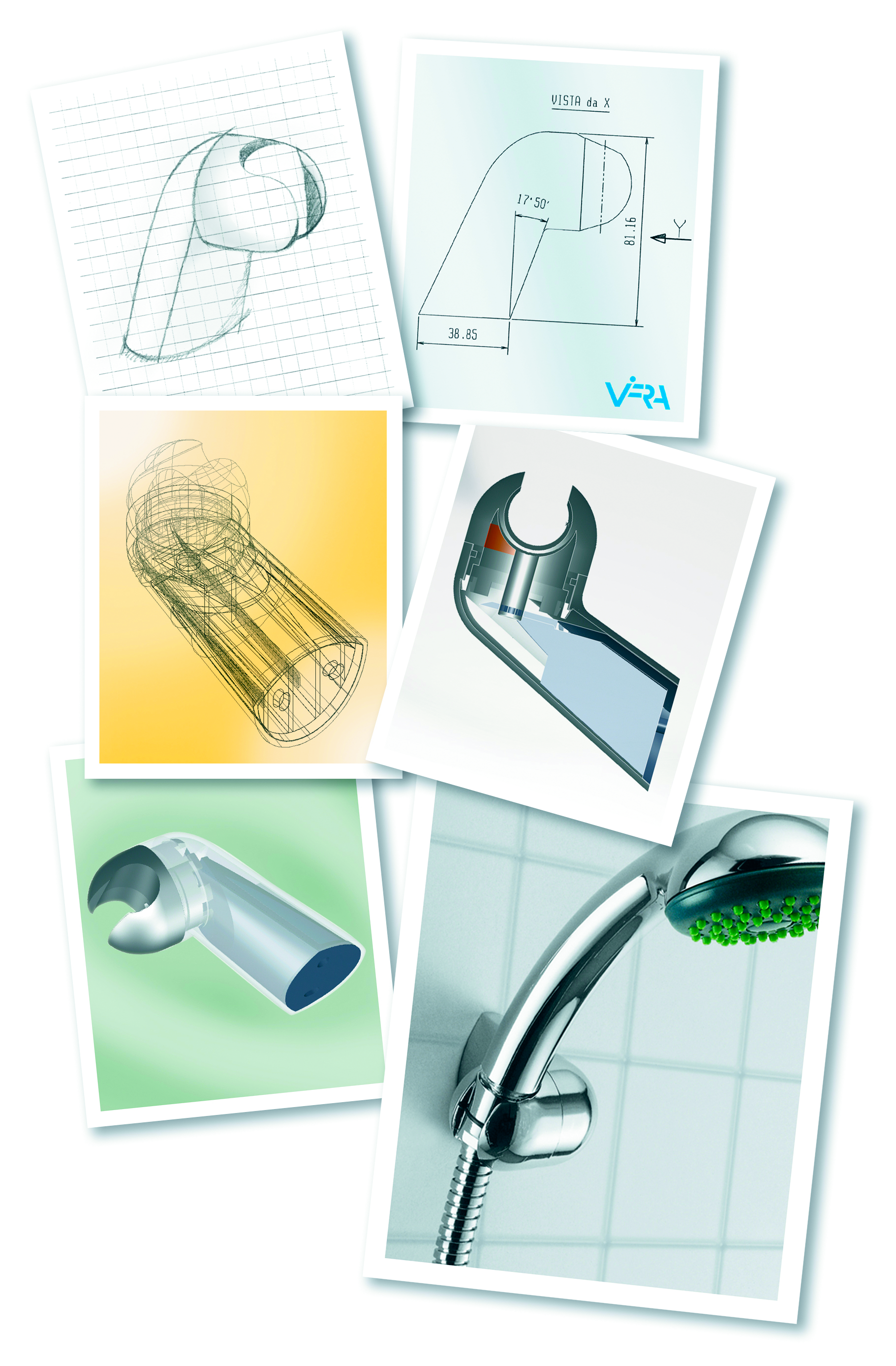

Design

Every item, every product that comes out of Vifra production, is the result of an idea, a solution designed to solve customer’s needs and requirements.

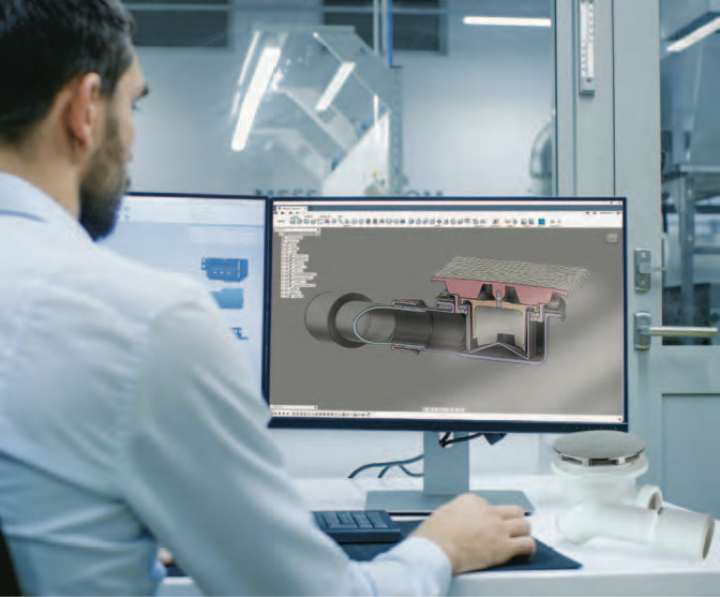

Everything therefore starts from a deep analysis of what you want to satisfy; we evaluate, together with the customer’s technical office, every variable and critical feature, until we develope an ideal solution, which is translated into a 3D project. We use the best technical drawing softwares to create scalable vector files in various formats such as DWG, DXF, DWF, CRG, 3DM and others.

The project is designed together with customer, in close collaboration, in order to have all the variables under control. This leads to a video drafting of what was only a conceptual idea, which becomes something that takes shape by analyzing needs point by point.

Everything therefore starts from a deep analysis of what you want to satisfy; we evaluate, together with the customer’s technical office, every variable and critical feature, until we develope an ideal solution, which is translated into a 3D project. We use the best technical drawing softwares to create scalable vector files in various formats such as DWG, DXF, DWF, CRG, 3DM and others.

The project is designed together with customer, in close collaboration, in order to have all the variables under control. This leads to a video drafting of what was only a conceptual idea, which becomes something that takes shape by analyzing needs point by point.

Prototyping

Together with design, we have the opportunity also to create three dimensional prototypes with the same physical and functional properties of what the final product will be. In this way, we have the possibility to “touch with our hand” what the final solution will be, to understand if it can meet needs and where we can improve the project. So the concept of continuous improvement can already start strongly in the design phase. 3D printing is a strenght of our design activity; samples and small pre-series productions are produced using classic prototyping methods or innovative additive manufacturing.

Reverse engineering

The development of an idea or solution can also take place starting from the re-engineering of an already existing object. Also in this case Vifra has the possibility to support the customer, through the use of digital optical scanners. In particular, with the use of laser technology, in addition to the use of classic CMM measuring machines, we are able to produce 3D objects, which faithfully reproduce the phisical object studied.

Bring your prototype, the object you want to reproduce, and we mathematize it, creating a 3D video copy, in order to optimize the idea and to study possible improvements before mass production.

Bring your prototype, the object you want to reproduce, and we mathematize it, creating a 3D video copy, in order to optimize the idea and to study possible improvements before mass production.

Tailor made

“If you can dream it, you can do it.” – Walt Disney

Bring us your idea, your needs, your sample, and we will study together the best solution for you.

Discover Vifra tailor made

Bring us your idea, your needs, your sample, and we will study together the best solution for you.