Quality System

Production parallel process, quality attends both in the product and in the process, guaranteeing a high level final result.

Quality System

Production parallel process, quality attends both in the product and in the process, guaranteeing a high level final result.

Quality control

Once the moulded product is obtained, it is checked and tested with qualified personnel and certified measuring instruments. Laboratory tests and controls with mechanographic system, burst pressure, aesthetic control with electronic optical system. The aesthetic control of the product is scrupulous and is constantly performed throughout the entire production process. VIFRA performs a double quality control procedure. The first in the molding department, the second in the warehouse for the chromed or assembled product.

Product Quality

The production is constantly checked and controlled by the department staff, supervised by the Product Quality Manager. At pre-established intervals, operators check each production of the 15 presses and of the assembly department, not only aesthetically, but also functionally and dimensionally. We use and store samples appropriately signed for each component made in Vifra, and also we have a physical archive of samples shared with the customer, to ensure the desired supply status.

Process Quality

Production process monitoring is the basis of continuous improvement, a philosophy that Vifra pursues every day, with the target of constantly improving quality, efficiency and effectiveness of what it produces. Following the indications offered by ISO9001 and beyond, the Process Quality Manager interacts daily with the Production Manager, the Product Quality Manager and with the same moulding operators, to find and study margins for improvement in work activities. Working by projects, every possible modification to the process is carefully studied, evaluated, implemented and verified following the logic of the PDCA (Plan-Do-Check-Act).

Warehouse Quality

Product and process control does not stop at the production department, but also continues in Vifra warehouses. Staff, following pre-established criteria and using the experience acquired over the years, makes daily checks of conformity of the material in Arrivals Acceptance. The raw material, the semi-finished products and the items being purchased are checked by sample or even 100% to obtain goods of the highest possible quality. Following the guidelines of the ISO9001 regulation, each supplier is evaluated and periodically inspected to have control over all the variables that influence Vifra process.

ISO 9001 and ISO 14001

Vifra ensures constant monitoring of its processes, having obtained the certificate of conformity not only to the ISO 9001 standard concerning the quality of the processes, but also to the ISO 14001 standard related to the respect of environment.

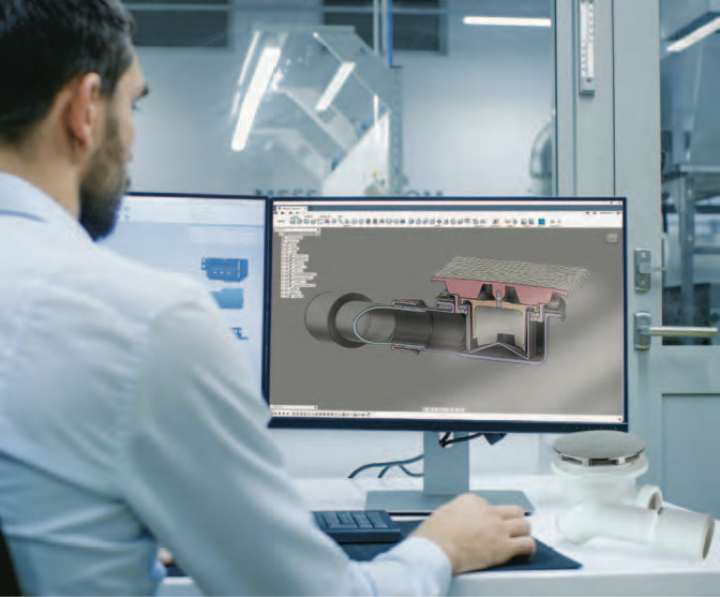

Tailor made

“If you can dream it, you can do it.” – Walt Disney

Bring us your idea, your needs, your sample, and we will study together the best solution for you.

Discover Vifra tailor made

Bring us your idea, your needs, your sample, and we will study together the best solution for you.