Mould development

The definition of the quality of the product depends on the careful study of the design of the mold. There are many aspects to consider: the number of forms to be inserted, the injection point, the extractors, the cooling zones and more.

Mould development

The definition of the quality of the product depends on the careful study of the design of the mold. There are many aspects to consider: the number of forms to be inserted, the injection point, the extractors, the cooling zones and more.

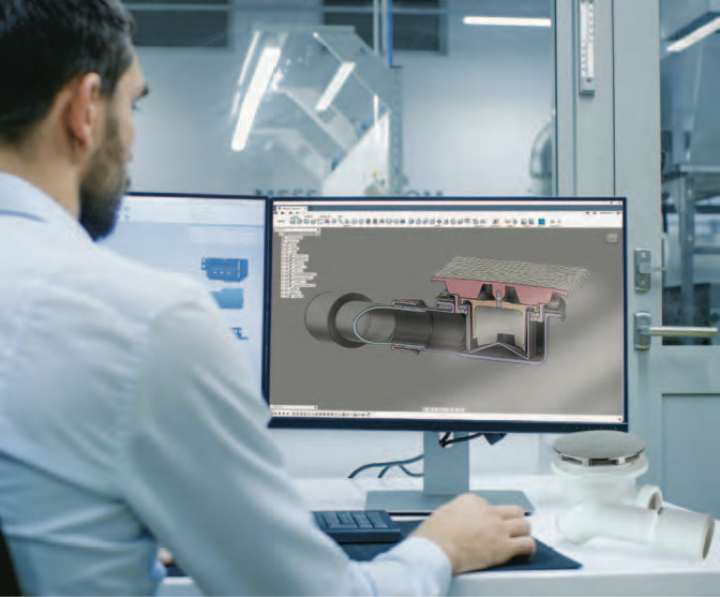

From design to mould creation

Our engineers are available to follow the industrialization of the initial idea. Stanting from initial design of the component, we use our know-how and experience to realize the 3D math of the mould, considering all the variables needed to obtain a solid and long-lasting result.

Accuracy in mould design is vital, as it gives solid foundations for the construction of reliable equipment; in the starting phase, experience allows you to find solutions considering critical and fundamental aspects, such as balancing of the injections, mould cavities, materials used, type of finish that the moulded object will have, and much more. The more variables I keep under control at the start of the project, the fewer the fine-tuning interventions are required before deliberating the mold for mass production.

Vifra staff acts to obtain a reliable project, always considering the possibility, with a view to continuous improvement, to make improvements at any time.

Accuracy in mould design is vital, as it gives solid foundations for the construction of reliable equipment; in the starting phase, experience allows you to find solutions considering critical and fundamental aspects, such as balancing of the injections, mould cavities, materials used, type of finish that the moulded object will have, and much more. The more variables I keep under control at the start of the project, the fewer the fine-tuning interventions are required before deliberating the mold for mass production.

Vifra staff acts to obtain a reliable project, always considering the possibility, with a view to continuous improvement, to make improvements at any time.

Tailor made

“If you can dream it, you can do it.” – Walt Disney

Bring us your idea, your needs, your sample, and we will study together the best solution for you.

Discover Vifra tailor made

Bring us your idea, your needs, your sample, and we will study together the best solution for you.