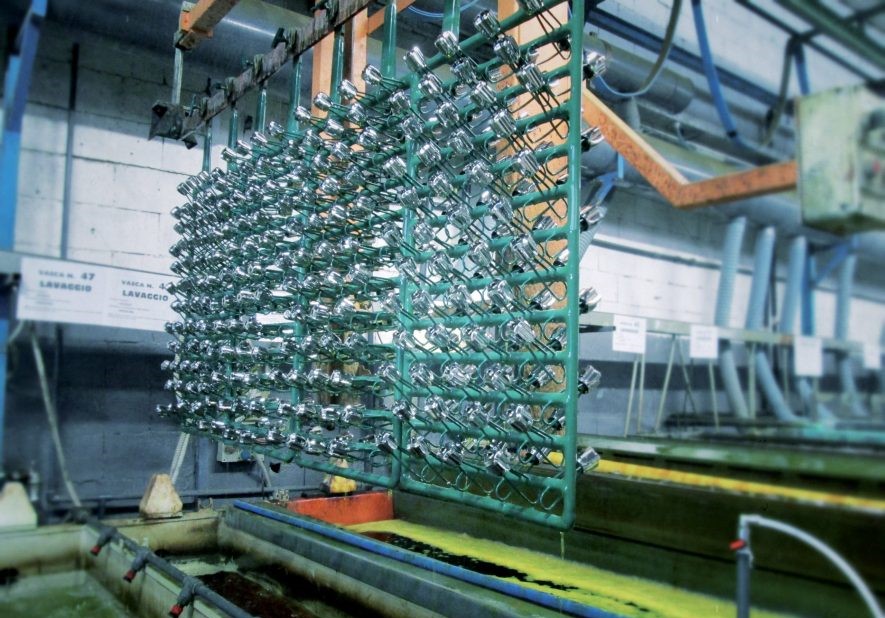

After the moulding process, finishing is of course another very important process of Vifra production chain. The Chrome Plating is the most prestigious Galvanic treatment for a plastic molded product. Once chromed, distinguishing a plastic object from a steel product can be hard.

In order to satisfy the customer needs, Vifra has many solutions available: from the classic galvanic treatment, which is the most requested, to other specific treatments.

Finishing

Finishing

After the moulding process, finishing is of course another very important process of Vifra production chain. The Chrome Plating is the most prestigious Galvanic treatment for a plastic molded product. Once chromed, distinguishing a plastic object from a steel product can be hard.

In order to satisfy the customer needs, Vifra has many solutions available: from the classic galvanic treatment, which is the most requested, to other specific treatments.

In order to satisfy the customer needs, Vifra has many solutions available: from the classic galvanic treatment, which is the most requested, to other specific treatments.

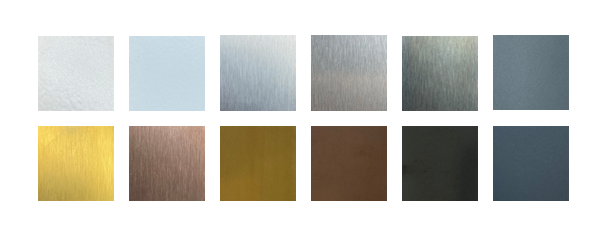

Vifra Finishes

To meet the Customer’s requirements, Vifra provides various finishes post moulding process, including those of the Colour range coming from a:

– galvanic treatment: • Chrome • Copper • Gold • Bronze • Brushed nickel

– powder coating treatment: • Matt black • Matt white • Various Pastel colours

– metallic treatment: • Different colours available

Vifra has trustable external partners who deal with the chrome plating and the finishing of our products, respecting the required quality standards. In addition, our Technical Office, following the Customer’s needs and requirements, is always ready to study any other type of finishing colour.

– galvanic treatment: • Chrome • Copper • Gold • Bronze • Brushed nickel

– powder coating treatment: • Matt black • Matt white • Various Pastel colours

– metallic treatment: • Different colours available

Vifra has trustable external partners who deal with the chrome plating and the finishing of our products, respecting the required quality standards. In addition, our Technical Office, following the Customer’s needs and requirements, is always ready to study any other type of finishing colour.

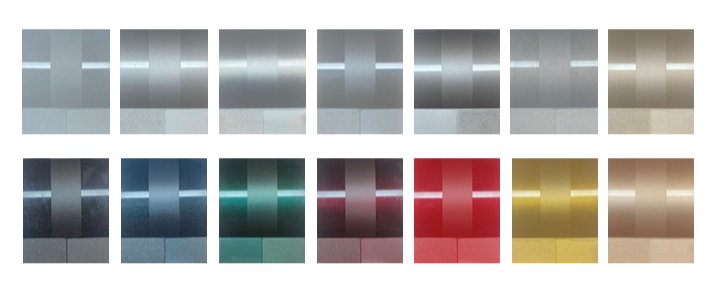

PVD (Physical Vapour Deposition)

Innovative finishing based on the physical evaporative deposition, through the vapor, of a thin film which allows to obtain a quality surface coating with thicknesses ranging from a few tenths of a micron up to more important values depending on the needs. This method offers several advantages:

– Quality aesthetical surfaces: uniformity, range and brilliance of several possible colours

– Functional features to the product: non-toxicity, the resistance to abrasion and atmospheric agents, stability and resistance of color and surfaces and a long-term maintenance of the aesthetic characteristics.

– Environmental sustainability: this method is completely ecological. All the phases of the coating process do not release harmful chemicals and do not pollute the environment.

Vifra PVD Collection: • Shiny Gold • Matt Gold • Shiny Rose Gold • Matt Rose Gold • Shiny Metal gun • Matt Metal gun

– Quality aesthetical surfaces: uniformity, range and brilliance of several possible colours

– Functional features to the product: non-toxicity, the resistance to abrasion and atmospheric agents, stability and resistance of color and surfaces and a long-term maintenance of the aesthetic characteristics.

– Environmental sustainability: this method is completely ecological. All the phases of the coating process do not release harmful chemicals and do not pollute the environment.

Vifra PVD Collection: • Shiny Gold • Matt Gold • Shiny Rose Gold • Matt Rose Gold • Shiny Metal gun • Matt Metal gun

The available PVD solutions are multiple and customizable. Depending on the color shade requested by the customer and the technical characteristics of the product, we suggest you the most appropriate type of coating.

Plastic finishes and innovative materials

Finishing that comes directly from the molding process, throughout the use of raw materials not burned: customized compounds, glitter additives, UV stabilizers, fillers. This finishing option offers a big color range and various alternatives to choose.

Customisation – After the finishig

Vifra really cares about providing you a customized finished product, for this reason, the Company offers other services like:

– Gloss finishing

– Brushing

– Screen printing (branded product)

– Lasering (branded product)

Vifra, also for these services, has reliable suppliers, who offer quality manufacturing.

– Gloss finishing

– Brushing

– Screen printing (branded product)

– Lasering (branded product)

Vifra, also for these services, has reliable suppliers, who offer quality manufacturing.

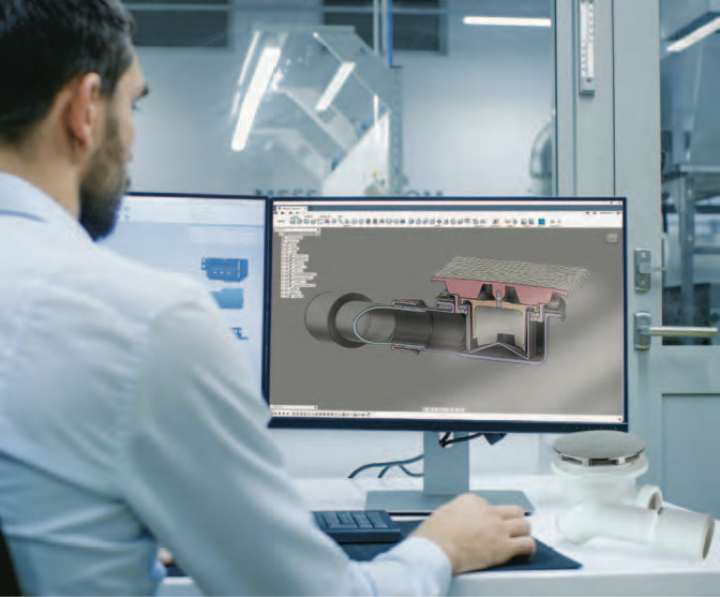

Tailor made

“If you can dream it, you can do it.” – Walt Disney

Bring us your idea, your needs, your sample, and we will study together the best solution for you.

Discover Vifra tailor made

Bring us your idea, your needs, your sample, and we will study together the best solution for you.