1980

By the will of Francesco Vicari lays the foundation for a future Vifra in Via Matteotti, Invorio.

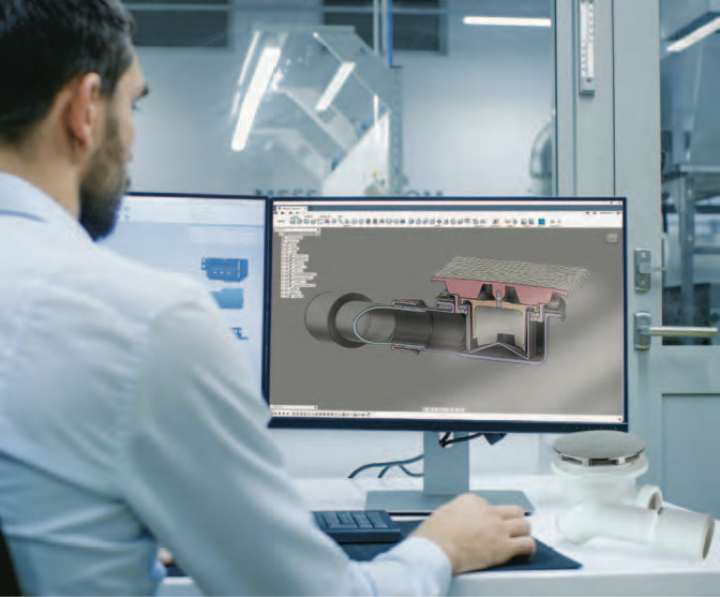

Vifra is a production Company, based in Invorio (in the province of Novara), able to design and mold Made in Italy plastic products for different sectors and with different materials and polymers. Our Vifra Team, thanks to its several technical skills, can create a product starting from the idea of a project, supporting the Customer to reach the wanted result and offering the finished product based on its needs and requests.

Vifra sets up, with the first small factory, in via Matteotti in 1984 in Invorio by Francesco Vicari, then passed on to his son Marino and now guided from the third generation. The Group currently has an area of 20000 square meters. 8000 of which are covered, consisting of a raw materials warehouse, a warehouse for finished and semi-finished products, a production warehouse, an assembly department and a head office.

The Made in Italy is synonymous of quality, reliability and originality of the design. That’s why Vifra’s production and supply chain are fully Italian: from the initial project, the prototyping, the purchase of raw materials, to the development of the mould and the customization of the product (through screen printing and lasering of your brand). In addition, Vifra offers services such as: finishing and chrome plating, assembly, packaging and shipping of the finished product.

In nearly 40 years, Vifra has cooperated with commercial sectors like: taps and fittings, cosmetics, perfumery, automotive, thermo-hydraulic, electronics, furnishing accessories and objects.

Vifra works 18 various types of polymers, which are kinds of plastic with different characteristics. Thanks to its experience and its know-how, Vifra is able to recommend the best material to use for each project and type of product.

We use the most modern raw materials for the industrial moulding, in order to guarantee durability and reliability of the items produced.

Knowing plastics properly help us creating environmentally friendly and sustainable products (from natural bio-based materials that are more easily recycled, compostable and biodegradable). Vifra knows the importance of plastic recycling and cares about adopting sustainable approaches that contribute to tackling the global plastic pollution crisis.

Vifra’s production site is composed by highly specialized machinery and technologies. The plastics molding department consists of 14 horizontal injection molding machines from 50 tons to 580 tons, and is capable of producing technical details with various materials in the range from 0.5 gr to 1000 gr.

The mold range owned by Vifra is made up of about 300 molds, while the molds owned by our customers are 200, who over the years have increasingly trusted Vifra, untrusting us with a fundamental part of their production.

The Vifra production department operates 24 hours a day from Monday to Saturday and it produces about 35 million pieces of plastic a year.

Vifra first injection moulding machine

By the will of Francesco Vicari lays the foundation for a future Vifra in Via Matteotti, Invorio.

Vifra was born in 1984. It was a craft activity placed in 50 square meters of the home’s garage.

Vifra approaches to molding withthe first electronic technologies experimenting new application fields of plastics. The same year Silvana Mastrolia draws the Vifra’s logo.

Under the leadership of Marino Vicari, Vifra moves away to via Vedani. Now it has 1.000 sqm disposal, and from laboratory becomes a reality with structured production cycles, quality control systems and automation processes.

Vifra moves in the actual headquarters, in via Barro in Invorio, a structure of 20.000 sqm with specific departments for production, warehouse and logistics.

Vifra’s production process is renewed by introducing a transport and dehumidification plant capable to convey automaticly raw materials from the silos to the molding workstations, without material dispersion also reducing energy consumption by 40%.

In the manufacturing process of the plastic is introduced the electric molding press. It has a less consumption, ensures a cleaner working and is more silent than the traditional hydraulic technology. Furthermore, allows to produce even more accurate with a lower environmental impact.

Vifra aim big to the world: the first international fairs are starting. Moscow and Libya open these shareholdings, in the meanwhile, Saudi Arabia, Kazakhstan and Dubai are booked for 2014 and in 2015 Vifra takes part to the ISH in Frankfurt. Vifra is also present and constant in Italy, participating at MCE in Milan.

Vifra obtains the ISO 9001:2015 Certification. This is an essential step for the Company to consecrate the investments made in recent years.

Vifra obtains the ISO 14001 Environmental Certification strongly desired by the Company with another contribution to have a production process with the best attention to waste disposal and respect for the environment.

Acquisition of a new plant used for the assembly and packaging department close to the others Company’s plants in Invorio.

Vifra has decided to invest in a digitization process inside the production department, aiming to improve and speed up the current activities and procedures.

The company invests in a digitization process inside the production department, improving and speeding up the current activities and procedure.

By 2025, the Company’s digitalization project will be completed in all its departments

Vifra is planning to invest in a photovoltaic system to increase our energetic efficiency, decrease our electrical energy costs thanks to renewable energy.