Injection moulding

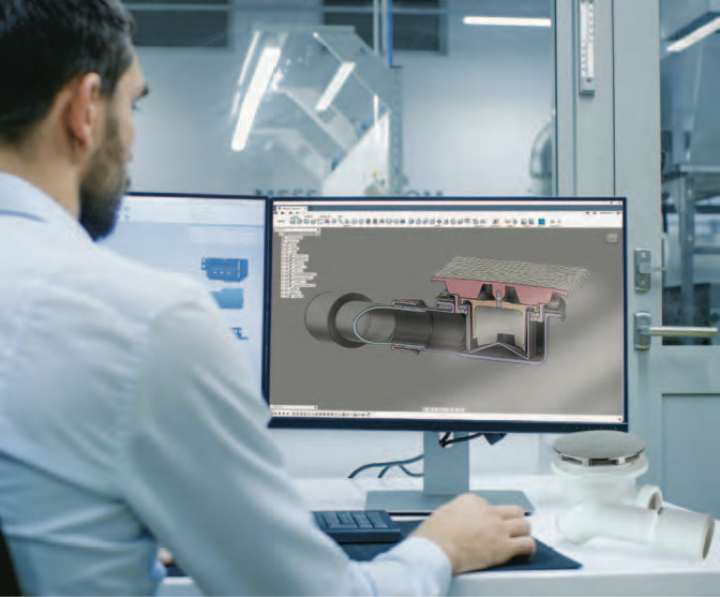

The injection processing technique is performed by inserting the polymers, plastic granular elements, into the press. Through a high temperature process the polymers melt and feed the mold through a screw cylinder. For compression and cooling, the plastic mass obtained in fusion takes the shape expected from the mold.

Injection moulding

The injection processing technique is performed by inserting the polymers, plastic granular elements, into the press. Through a high temperature process the polymers melt and feed the mold through a screw cylinder. For compression and cooling, the plastic mass obtained in fusion takes the shape expected from the mold.

“Production and Quality: Vifra hearth and soul”

Our core business: the injection moulding

The “engine” of Vifra is the production department, made up of 15 injection molding machines for plastic materials. The machines have a capacity from 50 tons up to a maximum of 580 tons, coordinated by the programming and production office.

In particular, the department includes:

1 – Injection moulding machine ARBURG, 50 tons with counting scale

2 – Injection moulding machine ARBURG da 100 tons with counting scale

3 – Injection moulding machine ARBURG da 150 tons with counting scale

4 – Injection moulding machine ARBURG da 150 tons with counting scale

5 – Injection moulding machine BATTENFELD, 80 tons

6 – Injection moulding machine BATTENFELD, 110 tons

7 – Injection moulding machine ENGEL, 80 tons

8 – Injection moulding machine BATTENFELD, 160 tons

9 – Injection moulding machine BATTENFELD, 180 tons

10 – Injection moulding machine BATTENFELD, 210 tons

12 – Injection moulding machine BATTENFELD, 180 tons

13 – Injection moulding machine BM BIRAGHI, 580 tons

14 – Injection moulding machine ENGEL DUO, 450 tons

15 – Injection moulding machine BATTENFELD, 350 tons

All moulding machines are equipped with robots and gripping hands that can be customized according to the product, and if necessary each process is configured to obtain maximum efficiency and the best possible quality. For this reason, automatic feeding conveyors of various types are used together with the robots, also with immersion in water, tanks for rapid cooling, blowers and cooling cages.

In particular, the department includes:

1 – Injection moulding machine ARBURG, 50 tons with counting scale

2 – Injection moulding machine ARBURG da 100 tons with counting scale

3 – Injection moulding machine ARBURG da 150 tons with counting scale

4 – Injection moulding machine ARBURG da 150 tons with counting scale

5 – Injection moulding machine BATTENFELD, 80 tons

6 – Injection moulding machine BATTENFELD, 110 tons

7 – Injection moulding machine ENGEL, 80 tons

8 – Injection moulding machine BATTENFELD, 160 tons

9 – Injection moulding machine BATTENFELD, 180 tons

10 – Injection moulding machine BATTENFELD, 210 tons

12 – Injection moulding machine BATTENFELD, 180 tons

13 – Injection moulding machine BM BIRAGHI, 580 tons

14 – Injection moulding machine ENGEL DUO, 450 tons

15 – Injection moulding machine BATTENFELD, 350 tons

All moulding machines are equipped with robots and gripping hands that can be customized according to the product, and if necessary each process is configured to obtain maximum efficiency and the best possible quality. For this reason, automatic feeding conveyors of various types are used together with the robots, also with immersion in water, tanks for rapid cooling, blowers and cooling cages.

The digitization

In 2022, Vifra has decided to invest in a digitization process inside the production department, improving and speeding up the current activities and procedures. Thus, the management and handling of the work cycles will be automated and the entire production process will be directly managed by the company management software.

Tailor made

“If you can dream it, you can do it.” – Walt Disney

Bring us your idea, your needs, your sample, and we will study together the best solution for you.

Discover Vifra tailor made

Bring us your idea, your needs, your sample, and we will study together the best solution for you.