Vifra believes in the constant improvement

Vifra strongly believes in the great potential that the injection moulding sector can offer, it invests in the development of its know-how and in the most modern technologies.

Vifra believes in the constant improvement

Vifra strongly believes in the great potential that the injection moulding sector can offer, it invests in the development of its know-how and in the most modern technologies.

Growth

In 1980 Vifra set up with the first factory in via Matteotti, in Invorio, in the province of Novara, Italy. In 1991 it moved to via Vedani expanding its production and in 2007 it moved to via Barro, expanding its plants even further.

Innovation

In 2009 we renewed the production chain with an automatic transport and dehumidification system, capable of conveying the raw material from the silos to the moulding stations without dispersion material, and reducing energy consumption by 40%, bringing greater savings, more order and efficiency in production.

In the manufacturing process of the plastic, in 2012, has been introduced the first electric molding press, more silent than the traditional hydraulic technology and able to ensure a cleaner work. Furthermore, it allows to produce even more accurate with less consumption and a lower environmental impact.

In the manufacturing process of the plastic, in 2012, has been introduced the first electric molding press, more silent than the traditional hydraulic technology and able to ensure a cleaner work. Furthermore, it allows to produce even more accurate with less consumption and a lower environmental impact.

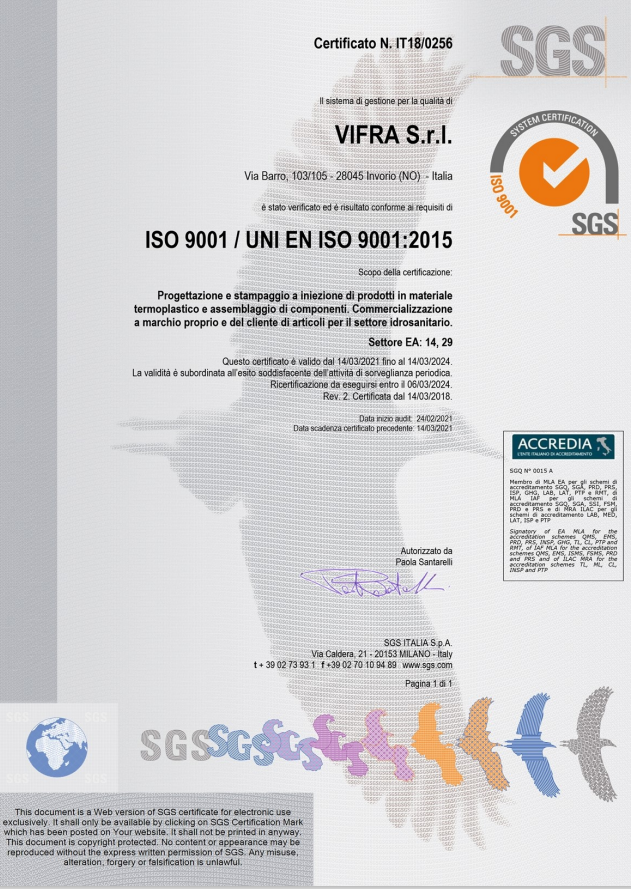

Our Certifications

In 2018 the company process has been subjected to all the necessary checks and has obtained the ISO 9001 Certification which is a guarantee of quality, reliability and an appropriate company structure.

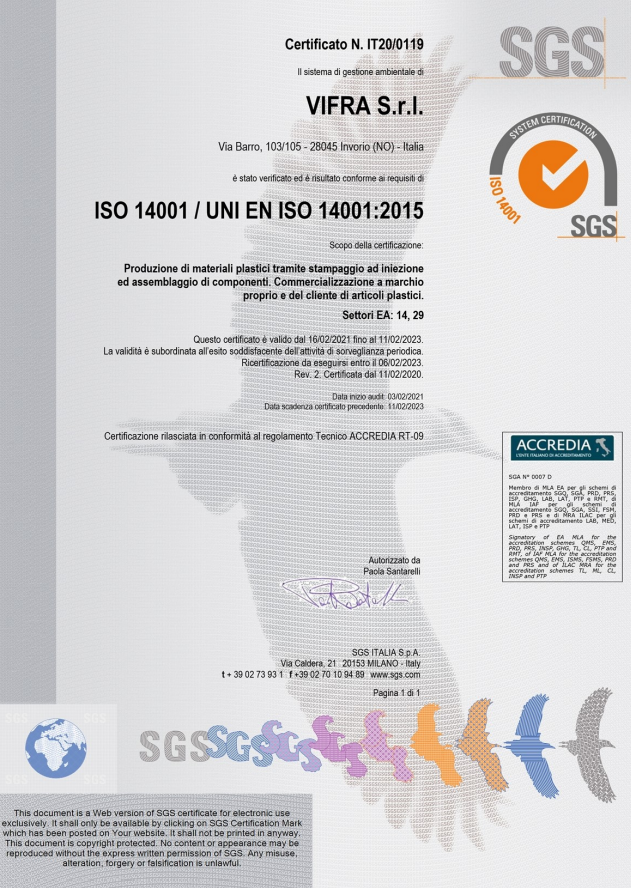

Vifra’s always been environmentally aware and careful to the surrounding area so that in 2020 has proudly obtained the ISO 14001 Certification.

Vifra’s always been environmentally aware and careful to the surrounding area so that in 2020 has proudly obtained the ISO 14001 Certification.

New opportunities

In 2013 Vifra aim big to the world. The first international exhibitions started with Moscow and Libya, in the meanwhile, Saudi Arabia, Kazakhstan and Dubai are booked for 2014 and in 2015 Vifra took part to the ISH in Frankfurt.

Improvement

In 2021 Vifra acquired a new plant used for the assembly and packaging department close to the actual plants in Invorio.

Digitization

Vifra has recently decided to invest in a digitization process inside the production department, aiming to improve and speed up the current activities and procedures within 2023. Thus, the management and handling of the work cycles will be automated and the entire production process will be directly managed by the company management software.

Tailor made

“If you can dream it, you can do it.” – Walt Disney

Bring us your idea, your needs, your sample, and we will study together the best solution for you.

Discover Vifra tailor made

Bring us your idea, your needs, your sample, and we will study together the best solution for you.